Toyota and Servco Pacific Inc. (Servco) have partnered to test a new car-sharing technology in Honolulu. The suite of software and services is an important part of Toyota’s Mobility Services Platform (MSPF) which will offer various functions to enable a more convenient mobility experience. When the employee-only pilot testing program concludes, Servco, the distributor of Toyota vehicles in Hawaii, will use the car-sharing technology to launch a new Honolulu-based car share business by the end of 2017.

The car-sharing application will support driver identification and authentication, plus payment and fleet management for car-sharing businesses. It also includes a Smart Key Box (SKB), which lets users lock and unlock vehicles via a smartphone. The application was developed in-house and is managed by Toyota Connected North America (TC), the global technology strategy business unit for Toyota.

“This new application demonstrates the power of combining Toyota’s unrivaled global manufacturing and technology capacity with dealers’ extensive local operations to provide consumers with more convenient options to move,” said Shigeki Tomoyama, President of Connected Company, Toyota Motor Corporation.

“This successful launch of the MSPF represents the next generation in car-sharing platforms and is Toyota’s global foundation for fleet management, car-sharing, and the future of mobility,” said Zack Hicks, CEO of Toyota Connected North America. “Its powerful and flexible API based platform allows us to quickly adapt to new market opportunities and support deployment of locally-tailored mobility services.”

Since January 2017, Toyota has been working with Getaround on the car-sharing pilot program in San Francisco, Calif., verifying convenience and usability of the SKB. Thanks to the pilot test with Servco, Toyota continues to enhance the car-sharing application and MSPF, which seeks to leverage the power of connected vehicle systems to support new mobility businesses. Eventually, Toyota will also begin working with other dealers and distributors to tailor the core technology for their markets, aiming for safe and more convenient, customer-centric mobility services.

Launched in 2016, TC was created to significantly expand Toyota’s capabilities in the fields of vehicle data science, machine learning, and contextual data services development, and provides a wide range of data and computer science services across Toyota’s global operations.

courtesy: pressroom.toyota.com

Toyota Motor Corporation announces the launch of its completely redesigned Camry in Japan and the start of sales at all nationwide Toyopet, Toyota Corolla and Netz dealers (including Tokyo Toyota dealerships).

The original Camry debuted in 1980 as the rear-wheel drive Celica Camry. Initially sold exclusively in Japan, it was renamed Camry in 1982 and was redesigned as a front-wheel drive sedan for global markets. Since then, the Camry has evolved into Toyota’s global midsize sedan, sold in more than 100 countries worldwide. Cumulative sales have topped 18 million vehicles5, including unparalleled success in the United States, where it has been the best-selling passenger car for 15 consecutive years6.

The new Camry design aims to test the limits of performance and intelligence, infusing the high-end sedan with a refined feel. The design team began with a blank slate, using Toyota New Global Architecture (TNGA) as the basis for the all-new platform, units, electronics, and other core components. The result is a striking emotional character, stunningly beautiful design, responsive driving, and premium ride performance. Augmenting these core features are a Human Machine Interface (HMI)7 to make driving easier, a high-class interior cabin with well-cut features, and state-of-the-art active safety systems. The new Camry redefines the standard for high-end midsize sedans.

Exterior Styling

The TNGA-based design has lowered the engine and passenger layout to create a striking silhouette emphasizing a low center of gravity.

Front

- Toyota’s original Keen Look* design philosophy instills the Camry with a unique character, juxtaposing a slim upper grille with a bold, three-dimensional lower grille. The low center of gravity accentuates the overall wide stance.

- The Bi-Beam LED headlamps feature three-level stacked LED clearance lamps that provide high-quality visibility, offering a wide periphery and range of vision.

Side

- The lowered hood and fender, along with low belt lines extending along the sides, accentuate the tires and low center of gravity.

- The rearward extension of the roof produces a more spacious interior and dynamic exterior proportions. Compact side windows lend the body a sporty, energetic feel.

- The rich intonations and sharp lines of the body combine to create glamourous molding.

Rear

- The wide stance produces a sporty look, while the raised shoulders lend a sense of stability and style.

- Striking LED lamps generate linear lighting, and the wide-set design evokes a sense of class.

Interior

- Spacious and sporty cockpit

The instrument panel has a sleek look and feel driven by TNGA’s vision, incorporating compact parts and an innovative layout. The new package, achieved by the lowering of the engine hood, cowl, belt line, and other features enables increased expansive outward visibility and results in a sporty, spacious interior.

- Merging advanced interfaces with sculpted form

The navigation display, color head-up display1, and multi-information display are integrated to present information in a way that optimizes the driver’s operational view and visual movements that allow the driver to focus on driving. The center cluster panel, which controls the navigation and heater settings, adopts a flush-surface2 design. The adoption of cutting-edge interfaces creates a point of distinction.

- A rich, distinctive feel and superior craftsmanship

The metallic instruments are arranged in a seamless flow, while multiple colors and materials are coordinated perfectly to create a singular look and feel, including the use of a tiger-eye motif for the ornament panel. Altogether, the interior has a distinctive sense of quality attained through the fastidious attention to materials and rich feel.

Platform

- The responsive driving performance originates from the optimal weight balance offered by the newly designed TNGA-based platform and exceptional vehicle stability. Additionally, with its lower center of gravity, the Camry achieves exceptional stability and minimal sway during high-speed driving.

- All four of the engine mounts are hydraulic engine mounts (a first for Toyota), and the optimized placement of the mounts minimizes vibration and noise to ensure an exceptionally smooth ride.

- The suspension features newly developed MacPherson struts in front and double wishbone format in the rear, ensuring responsive driving and premium ride performance.

- The parallel rack electronically controlled power steering features responsive handling. The newly developed steering column enhances rigidity and improves steering ability.

Body

- The body adopts a ring-shaped frame which limits torsional movement to ensure superior control stability. Body rigidity is further enhanced through the use of Laser Screw Welding, a state-of-the-art welding method for vehicle bodies, and structural body adhesives. The extensive use of ultra-high-tensile hot-stamp steel throughout the Camry reduces its weight while improving collision safety.

Powertrain

- The new Camry combines an all-new TNGA-based 2.5-liter Dynamic Force Engine, offering maximum thermal efficiency of 41% and high output, with the ever-improving hybrid system (THS II) to deliver fuel efficiency of 33.4 km/liter―top class among vehicles with similar engine displacement―and exceptional driving performance.

courtesy: newsroom.toyota.co.jp

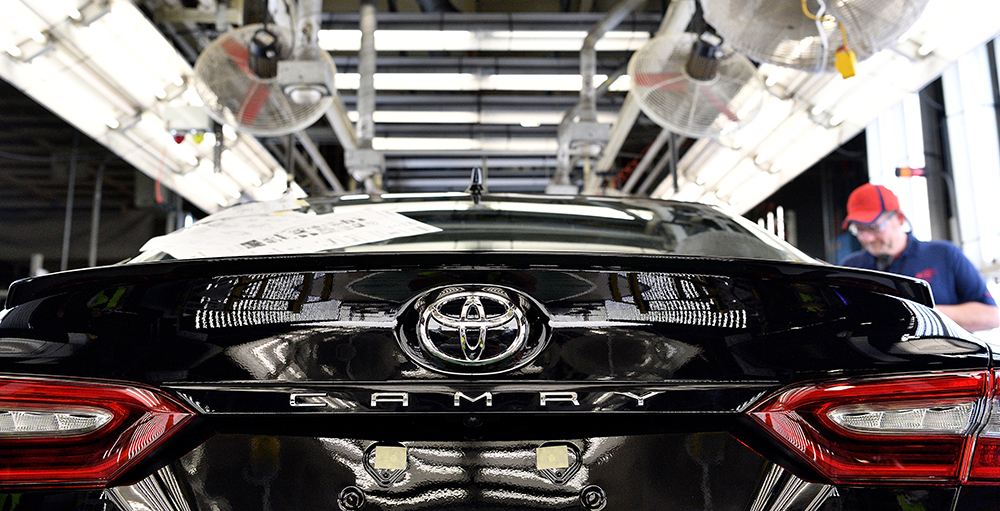

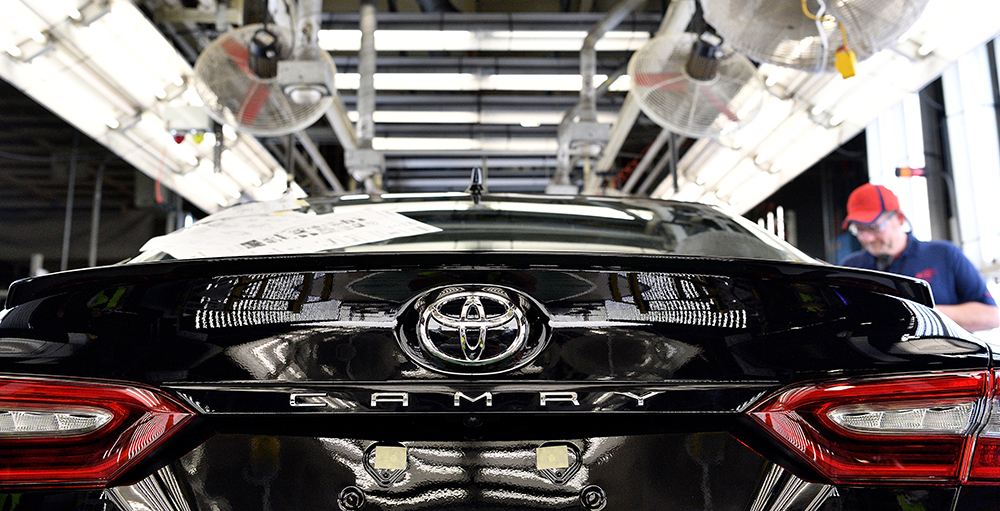

Chad Lindon has worked at Toyota in Georgetown, Ky., for 22 years and said the 2018 Camry is the most exciting vehicle launch he’s seen, and for good reason.

“The 2018 Camry takes it to another level,” said Lindon, a Powertrain production team member. “It catches the eye. It has more horsepower, better fuel economy, and new technology that customers want. That all adds up to more job security and stability for my family.”

The excitement that has been building for months peaks today inside Toyota Motor Manufacturing, Kentucky, Inc., (TMMK) as team members celebrate the launch of production of the 2018 Camry. The automaker is upping the ante by crafting an ever-better Camry that boasts an exhilarating design, refined interior, stirring driving performance, cutting-edge safety and technology, and class-leading fuel efficiency.

Lindon and co-worker Maigen Layne can’t wait to see the new models on the road. Layne, a five-year team member who works as a safety team leader in bodyweld, says “it’s the best one so far,” and plans to make it her next car. “I’m proud to work on the best-selling car in America for 15 years running. I test drove one of the first 2018 models off the line and I know it will be a big hit.”

The 2018 Camry will set the benchmark in the mid-size sedan segment. It is the first vehicle in North America designed and manufactured with Toyota New Global Architecture (TNGA), a completely new strategy to the way the company designs, engineers, and manufactures its vehicles. TNGA will improve performance of all models, including increased fuel efficiency, more responsive handling, and a more stable, comfortable feel while driving.

“The launch of the next-generation Camry is important for Toyota in America, and expands the company’s footprint in and commitment to Kentucky,” said Wil James, president, TMMK. “We are proud to be the first in North America to produce a vehicle with TNGA. It’s a testament to the skill and dedication of our team members.”

The next-generation Camry has a sleeker profile that offers improved aerodynamics, a lower center of gravity, and a more rigid body, allowing for a more comfortable and stable ride. In addition, engineers incorporated a number of new noise, vibration and harshness (NVH) countermeasures that were previously found exclusively on luxury models such as sound-absorbing insulation in the hood and upper and lower fender separator, as well as foam/vibration dampening materials throughout the vehicle. The driver-focused design also features the highest grade of soft touch and premium materials on all surfaces of the cabin – dashboard, instrument panel, center console, door trim, etc. Vehicles will begin arriving at dealers in late summer.

TMMK recently hired more than 700 people to support the launch of the new Camry, bringing the number of team members to an all-time high of over 8,000. The largest Toyota plant in the world, TMMK has produced more than 11 million vehicles in its 31 years, including more than 8 million Camrys.

Earlier this year, Toyota announced a $1.33 billion investment at TMMK for TNGA improvements and other makeovers that will modernize and streamline the production process. TNGA allows for a more flexible production environment, which will allow Toyota Kentucky to build ever-better cars and respond quicker and more capably to customer demands down the road. Since 1986, the plant represents a $7 billion investment. Across the U.S., Toyota is investing $10 billion over the next five years, adding to the nearly $22 billion the automaker has invested in the past 60 years.

Last year, TMMK produced more than 500,000 Camry, Camry Hybrid, Avalon, Avalon Hybrid, and Lexus ES 350 vehicles, which represents nearly a quarter of the total number of Toyota vehicles produced in North America. A recent study by the Center for Automotive Research shows Toyota Kentucky supports nearly 30,000 jobs across the states (direct, indirect, and spin-off). TMMK employees live in 80 Kentucky counties, and currently Toyota has more than 100 suppliers located across the Commonwealth.

courtesy: toyotanews.pressroom.toyota.com

Toyota Motor North America, Inc. (TMNA) is celebrating the official opening of its new North American headquarters today in Plano, Texas with a gala event to be attended by hundreds of dignitaries, partners and community leaders who will get the first glimpse of Toyota’s new corporate campus that reaffirms the company’s longstanding commitment to the United States.

“The opening of our new headquarters in Plano is an extraordinary next step in Toyota’s 60-year journey in the United States,” said Jim Lentz, CEO of Toyota in North America. “With team members from four different companies together in one campus location, we believe this will inspire greater collaboration, innovation, and faster decision making as we turn to and lead the future of mobility, all with an eye on our customers.”

Lentz added, “We appreciate the support from President Trump of our continued commitment to investing in the U.S. and sustaining American jobs.”

Congratulating Toyota on its grand opening, the company received a written statement from the White House, signed by the President. [attached]

Three years ago, Toyota announced its “One Toyota” initiative to create more unified operations in North America, in part, by bringing together its quality engineering, sales, marketing, financial services, and corporate functions in one location.

Since then, the company has invested about $1 billion on the project to build its new corporate campus on 100 acres in Plano and move thousands of team members and their families from California, Kentucky and beyond to North Texas. With construction nearly complete, occupancy began in late spring, and an average of a couple hundred team members per week are moving in, which is expected to continue in phases through December.

Celebrating its 60-year anniversary in the United States this year, Toyota has long been part of America’s cultural fabric. Toyota’s U.S. commitment includes:

- $23.4 billion in direct investment,

- 10 manufacturing assembly facilities around the country,

- Nearly 1,500 Toyota and Lexus dealerships, and,

- 136,000 direct and dealer employees.

In addition, earlier this year, Toyota said it will spend $10 billion in U.S. capital investments over the next five years, an outlay that includes the construction of its Plano headquarters and improvements to its existing manufacturing facilities.

The company will have jobs for up to 4,000 Toyota team members in Plano. In addition to the employees who chose to relocate, Toyota previously announced that it would hire more than 1,000 new team members from the rich mix of local talent and elsewhere. More than 90 percent of the company’s new hires from the past year for positions in Plano have come from the North Texas market. Toyota has already filled more than 75 percent of its open positions.

“The greatest resource we have here in the Lone Star State is our highly-skilled workforce that draws global businesses like Toyota to Texas every day,” said Governor Abbott. “The 4,000 jobs added and Toyota’s impressive new facility are proof of the remarkable momentum of Texas’ continuing economic expansion. I am proud that Toyota is expanding here, and I thank them for their commitment to being an important part of our Texas community.”

New Corporate Campus Inspired by One Toyota Vision, with Focus on Sustainability

The new campus supports the company’s One Toyota vision with spaces that intentionally create and foster a transparent environment, encourage the fun of discovery, and make Toyota a place where people want to come to collaborate and innovate. Among the seven buildings is a large central courtyard that serves as the literal and symbolic heart of all social and business functions – including dining, fitness, and conferencing facilities.

Additionally, Toyota demonstrates its commitment to sustainability with consideration for the environment as it aims to achieve LEED Platinum certification from the U.S. Green Building Council by offering:

- Exterior landscaping reflects the native habitat, with drought resistant plants

- A Texas-sized 8.79-megawatt array of more than 20,000 solar panels

- A commitment to use only renewable energy, purchasing all electricity not generated by the solar panels from wind generated by Texas farms

- A rainwater harvesting system, up to 400,000 gallons, to use in irrigation

“Our new campus has fun, unexpected, and even playful features that reflect our commitment to be a world-class leader in innovation with state-of-the-art facilities and cutting-edge technologies,” said Doug Beebe, general manager of real estate and facilities for Toyota Motor North America. “It also is a great example of Toyota’s commitment to environmental sustainability. Because of its architecture, its central location, and the lively, flourishing community around it, we can share ideas and make great things happen here. We are proud of this campus because we have designed it to allow team members to get out of their office space and come together. And, that’s really the spirit of One Toyota.”

Professionals who led this project include a host of Dallas-based firms: KDC Real Estate Development & Investments to develop and build the campus, architect Corgan Associates to design the campus, and Austin Commercial to manage the construction. Also, commercial real estate firm JLL was the tenant representative. Construction at the campus included the pouring of more than 142,500 yards of concrete, installation of more than 12 acres of glass and enough Texas limestone to equal the weight of 340 Texas-built Toyota Tundra 1794 Edition trucks. At its peak, there were approximately 2,000 workers on site daily, putting in more than five million hours of work on the project.

Campus Opening Marked by Celebration with Local Dignitaries, Celebrities

To mark the occasion of the opening, the company is holding a special celebration for [more than 300 / nearly 350 guests.] Speakers will include Jim Lentz, Plano Mayor Harry LaRosiliere, and other Toyota and other local government representatives.

“We are so pleased to finally welcome all of Toyota’s team members to Plano and celebrate the opening of this wonderful new facility,” LaRosiliere said. “Toyota has already proven to be a great corporate citizen and neighbor, and we look forward to the continued impact it will have not only on Plano, but on the whole North Texas region.”

Guests will be welcomed with a musical performance by the local Plano Symphony, performance by vertical dance group pioneers, Bandaloop; as well as a fine dining experience from noted celebrity Chef Dean Fearing. Tours of the new campus will also be provided as part of the evening’s activities.

courtesy: pressroom.toyota.com